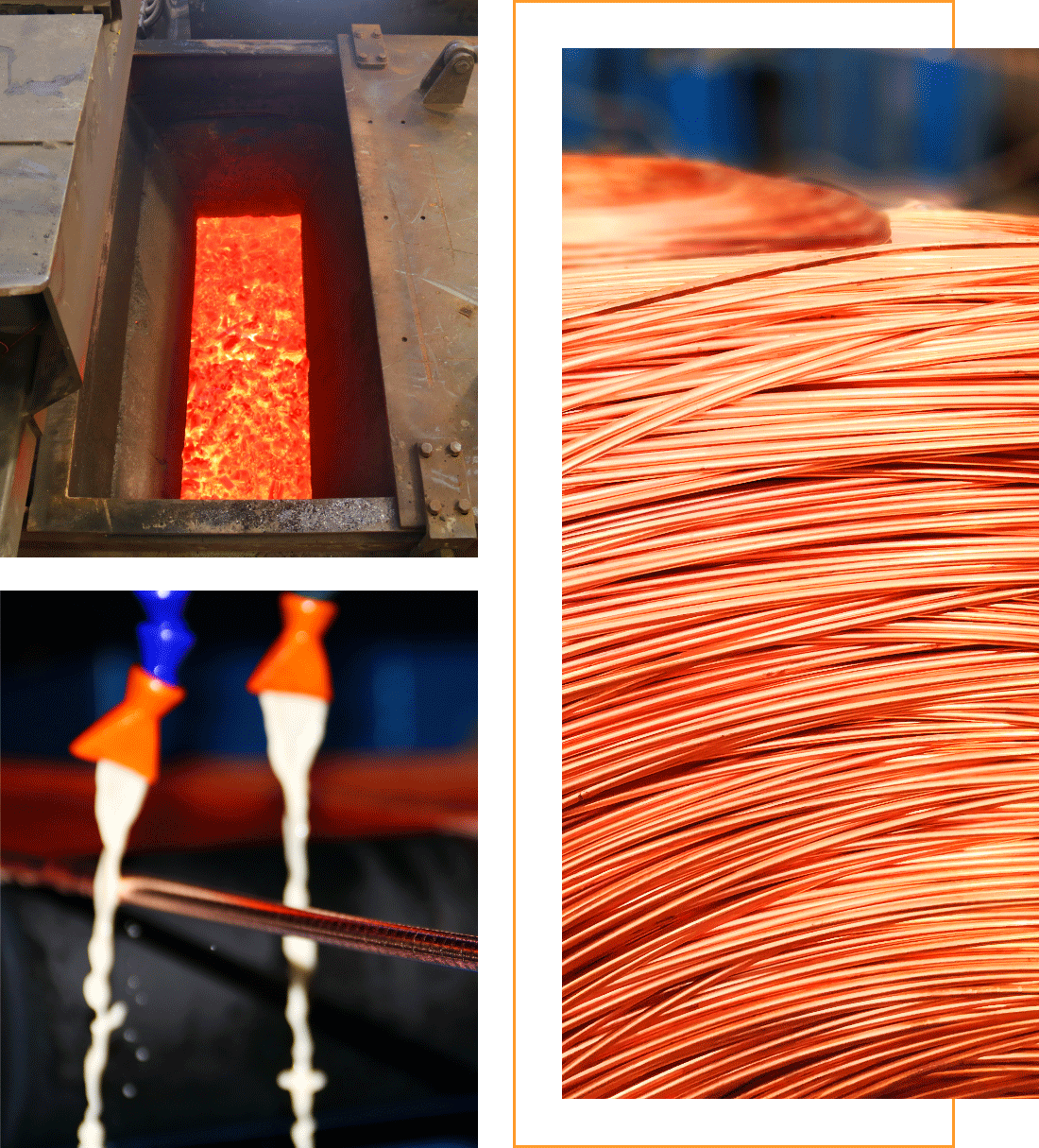

Manufacturing Process

-

/01 Production

- Raw materials is high quality copper cathodes

- Production capacity 15000 TPA

- Properties:

- - diameter of cast rod 8mm

- - the surface of wire rod is clean and smooth

- - electrical conductivity min 101% (IACS)

- - resistivity max 17.070nΩm

- - tensile strength approx. 170 N/mm2

- - elongation approx. 45%

The plant depend on UPCAST technical continuous casting system to produce high conductivity oxygen free copper wire rod ( 8mm cu: 99.99 % )

-

/02 Packing

The copper rod is supplied in coils of Aprox 3500 kg weight. The coils are packed on strong wooden pallets, firmly secured by four steel straps and covered by thick sheet of polyethylene.

-

/03 Marking

- - Manufacturer / Trade mark

- - Net / Gross weight

- - Coil production number

- - Production number

Each coil shall be prominently marked as follows:

-

/04 Quality Control

- - Oxygen test - This determines the oxygen content in copper

- - Chemical composition test using spectroscopy technology to determine the chemical composites of the produced copper rods.

- - Surface oxide measurement-elecrolyric removal of the surface oxide is used to determine the type and thickness of the oxide scale.

- - Conductivity - precision instrument measures the conductivity of copper.

- - Twist test - the rod is twisted back and forth ten times each and is then visually inspected.

- - Elongation and Tensile test - the rod is tested for elongation at fracture and for tensile strength.

- - Diameter checks - these guarantee that the rod are correctly round and of the required diameter.

All important parameters are continuously tested to provide quality control. The following tests below ensure the rod produced is consistent of high quality.